Pneumatic Control Specialists

Airlane Pneumatics are a family run business based in the North East of England. We have over 35 years of specialist experience helping you to maintain and upgrade manufacturing and automation processes with the innovative use of process, electro-pneumatic and pneumatic control equipment.

Making Pneumatics Work for You

By engaging with Airlane you get the right component at the right time. We believe in supplying the best pneumatics for your issue as quickly as possible.

What is Compressed Air?

(Compressed – the air or gas is forced into a smaller space and is always wanting to expand back to its’ original state of lowest energy level. If a sealed container has its’ volume reduced by 50% or halved then the pressure for the same amount of gas will double. Similarly, reduce the volume to 25% or ¼ and the pressure increases to 4 times the original. This then gives us a controllable energy source we can use to do useful work.

Compressed air and pneumatic control is now regularly used to replace many manual operations. This reduces operator injury, from both RSI related issues and by being caught in the workings of the mechanism itself. Also, production time, costs, quality all benefit from pneumatic automation. Pull, Push, Lift, Close, Open, Remove, Hold Fast, Operate, Feed, Squeeze – all easily achieved with pneumatics.

Probably the simplest way to generate compressed air or increase air pressure is a bicycle pump. When the pump is attached to the tyre the handle is forced down, pushing the air into the tyre.

Other simple examples include a perfume atomiser, windsurfer sail, trumpet, blowpipe, windmill sails, aerosol and air brush.

We are probably more familiar with more industrial applications like lorry air brakes, pneumatic roadside drills, dentist drills and the brushes on automatic car washers.

There are several advantages to you using compressed air as an energy source. The components are relatively inexpensive and pneumatic control accuracy will cover most applications, whether your application is in the automotive industry, food or pharmaceuticals for life saving drugs and medicines and everywhere in between.

However, specifying the correct components can be a huge task when presented with the huge tomes manufacturers refer to as basic catalogues.

Having worked with and alongside the world’s largest manufacturers, Airlane are well placed to offer advice and pricing when specifying pneumatic or process control components needed to run your application efficiently.

Benefits of pneumatic control include:-

✅ Very Controllable – both flow and pressure can be adjusted to suit the application

✅ Can be stalled – will not burn out motor unlike electric motors

✅ Cleaner medium – can be exhausted to atmosphere unlike hydraulics

✅ Usually available – almost all factories have a compressor installed

✅ Adverse conditions – can be used in explosive or dangerous atmospheres

✅ No need for insulation – Pipework doesn’t need protecting from temperature changes or dangerous when in contact with people. Doesn’t freeze or electrocutes.

✅ Relatively safe – no risk of explosion, care taken to avoid contact with body

✅ Low cost of capital equipment

Making the Complicated Simple

Airlane believe in keeping our pneumatic applications accurate, robust and, above all, simple. Working with Airlane you have the confidence that what you ask for, regardless of the complexity, is what you get, nothing more, nothing less.

There are many questions asked about pneumatic control including how big, how fast or slow, what pressure, what size and ‘how can I get this to do that’? Pneumatics and pneumatic control is a series of simple building blocks that link together to create robust and operational automated machinery.

By understanding your application, Airlane offer pneumatic sequence circuit design. We take your sequence, any adjustable parameters and factor in health and safety considerations to produce reliable, repeatable and, ultimately, safe circuit designs for any application.

Once designed we specify the correct components for each application. We look at our breadth of suppliers and check which parts are most suitable, readily available and cost effective for the application.

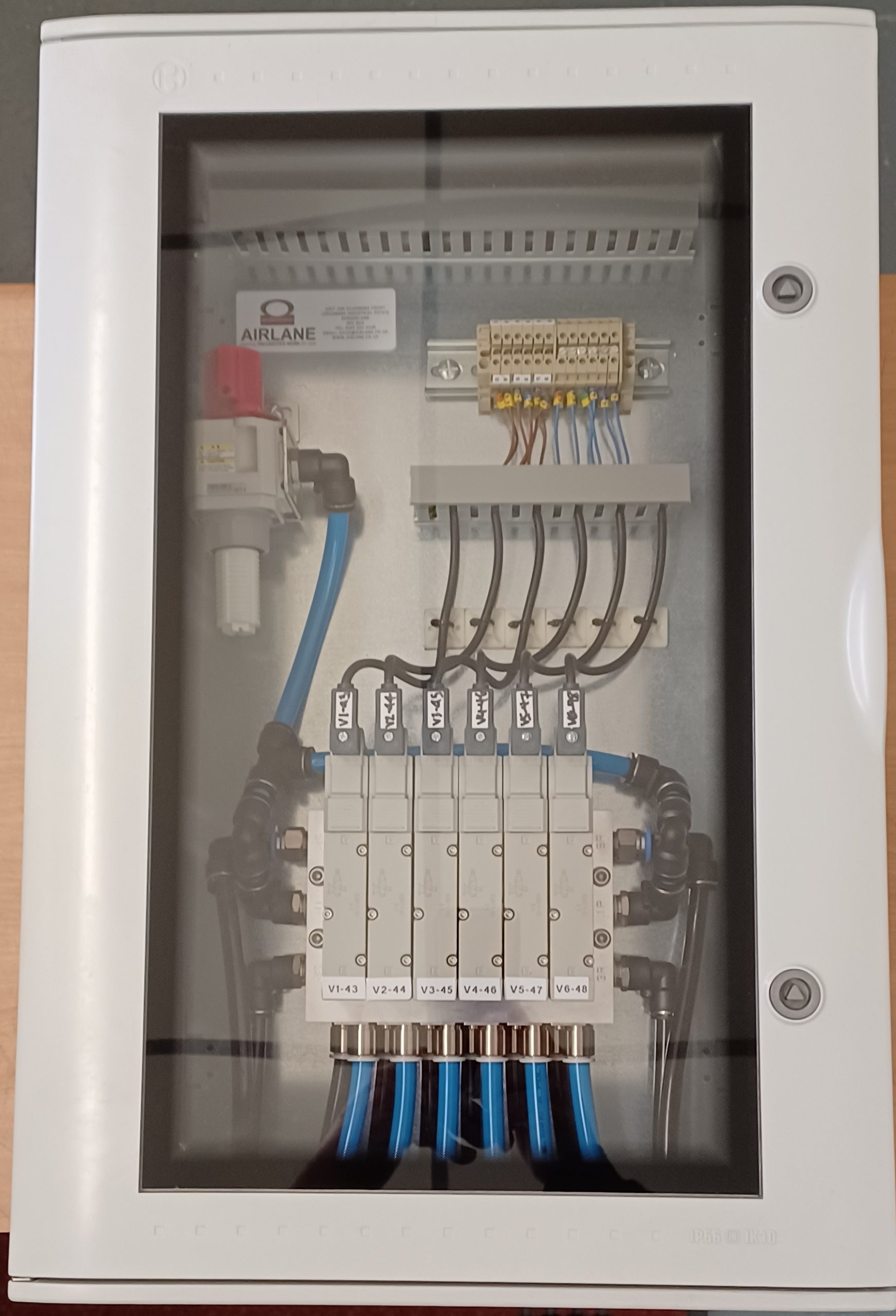

Still unsure what to do with this box of components? By asking Airlane to build the circuit into a purpose built enclosure to your specification we guaranteed that the circuit we design for you is installed correctly, all components and the control sequence rigorously tested before delivery to site and supplied fully labelled with instructions and circuit diagram for ease of operator use.

For examples on how we really do ‘make the complicated simple’, visit our project gallery.